Super-Customised Machinery to harvest lavender

Bonino lavender harvesting machines are tailor-made to meet the most specific needs.

Bonino machinery configuration

Every Bonino machine is custom designed and built to meet the most specific needs.

All the features of each machine are decided on with the customer: dimensions, cutting systems, harvesting systems, loading capacity, etc.

Each machine is built with a specific configuration based on the species of lavender that will be harvested, the type of soil (clay, alkaline, etc.), the various pedoclimatic conditions, and any other specific needs the farmer may have.

Every machine is one-of-a-kind

Each being so different from the next due to customer needs, Bonino lavender harvesting machines cannot be contained in a standardised range. However, as an example, Bonino can show you the features of some machines they have built and that are compatible with your specific requirements.

The technical aspects in brief

Product lifting brushes

The front brushes gently lift the entire product and move it towards the cutting system.

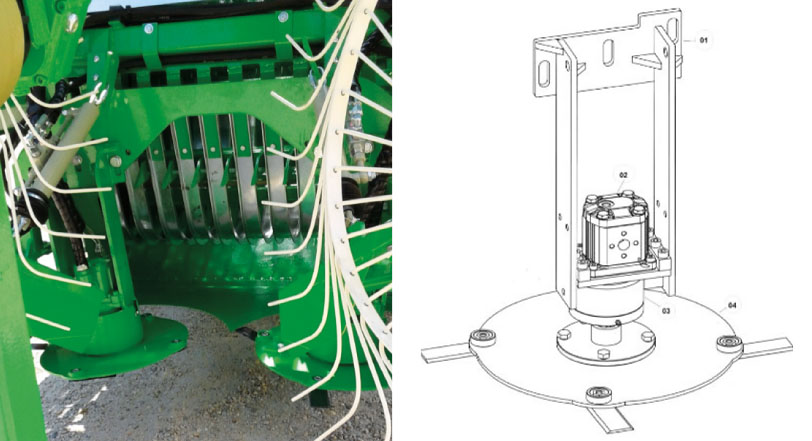

Cutting system

The cutting system is made up of tilting discs that make a clean cut, respecting the shape of the plant.

Lavender loading

A loading ladder conveys the cut product to the rear bin. The special shape and size of the ladder make it possible to load both long and short products.

Lavender unloading

The lavender can be unloaded to the ground in two ways:

– using a rear hydraulic door

– using a roller chain that unloads the product directly into bins or trailers.

An electrical-hydraulic system controlled by a pushbutton panel in the tractor cab controls the unloading system.

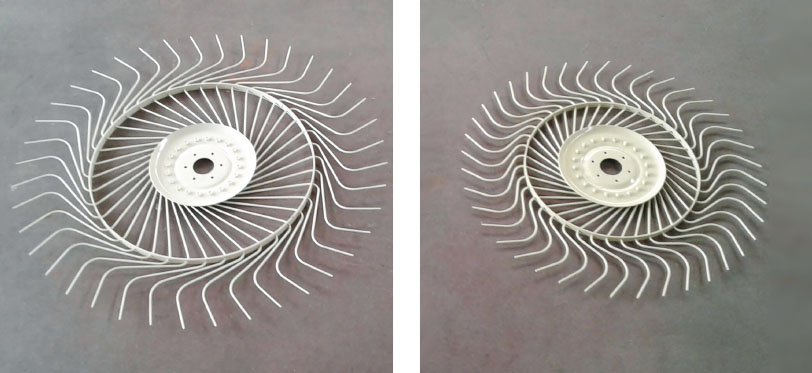

Conveying system

Two side spoked elements convey the plants to the middle of the machine: the product is gently pushed towards the middle so that the entire width can be cut. The spoked elements come in two different sizes, depending on the type of lavender or product to harvest.

For more delicate products, the machine can be fitted with propylene rings: they have the same function as the spoked elements but have a gentler approach. A specific adapter kit is available to install the rings on the machine (even after the machine has been purchased).

Cutting height

The dual-disc cutter bar allows cutting height, width, and angle to be adjusted.

The two discs can be tilted to find the cutting angle most suited to the product being harvested, considering the height of the plants and keeping the shape of the bush intact.

The cutting angle is of vital importance in order not to damage the plant and to ensure it grows back healthy for the next harvest.

Each cutting disc has 4 blades that cut the product cleanly and accurately.

By varying the cutting height, the same machine (BE model) adapts perfectly to harvesting either lavender or lavandin.

Cutting height can vary from 5 to 60 cm.

Unloading System

Hydraulic door:

allows the product to be unloaded to the ground, creating one or more piles, which will then be put into containers using specific forks, front lifters, grippers. or conveyor belts for the next step of extracting the essential oil.

Unloading at height:

allows the freshly harvested lavender to be unloading directly into specific containers, trailers, or lorries and transported to distilleries or other processing locations.

Another option that this type of unloading permits is emptying the lavender directly into distillers for essential oil extraction.

With both methods, it is possible to unload the lavender on the ground, slowly moving forward to create a carpet of product that can dry evenly in the sun. Fragrant bouquets can later be made.

Or the lavender can be brought to a distillery to be transformed into essential oil.

Axle track, Axles, and Tyres

Axle track from 1300 to 1700 mm

The lavender cutter bar has 4 axles with variable axle tracks, depending on the crop.

The axle track can vary from 1300 to 1700 mm.

Types of tyres

You can choose from among different types of tyres, depending on the terrain: wider tyres for friable soil or to give greater stability; all-terrain designs; tyres with or without inner tubes.

You can also request a spare tyre kit to be installed, which includes: a spare tyre mounted on the rear door or supplied separately, support feet to change the tyre, machine configured for tyre change.

Other features

Electronic pushbutton panel

All the machine functions are activated using an electronic pushbutton control panel located inside the tractor cab. The operator can cut, load, and unload the product without ever leaving the tractor.

Radiator

A specific radiator was designed and introduced to allow operators to work even in locations with very high temperatures or so as not to stress the hydraulic system after many consecutive hours of work.

Selecting cutting height

Product cutting height can be selected using a specific measuring stick.

Access to the bin

There is a side door to access the bin, made easier by a side ladder in the event of rear unloading at height.

High tiller

The high tiller allows the structure of the machine to clear the products to be cut and those that have been cut without damaging the plants.

Automatic lubrication

The self-loading conveyor is automatically lubricated, ensuring constant drip feed lubrication of the roller chains on each side of the product conveyor chain.

The various internal grease points are easily accessible.

Please fill this form

We will get back to you asap

BONINO s.r.l. – Via Torino, 173 – Sommariva Bosco (CN) – Italy – Tel. + 39 0172.54132 – Fax + 39 0172.560942 – info@boninoitaly.com – P. IVA 01653320042

Copyright © 2021 Bonino s.r.l. – All rights reserved – Legal statements | Privacy | Credits